Circular saw blades for metal DIN 1838 B with rough teeth and teeth form B are recommended especially for cutting-off steels. In comparation with teeth form A they have much bigger chip clearance and they enable bigger cut. In standard modification the saw blades are made with hollow ground and with flange. They can be ordered with teeth form BW( the teeth form B with alternate chamfering)

金属加工用锯片铣刀标准,德标DIN 1838 B 粗齿型和B型齿,主要适用于钢件的切断。 与DIN 1837 A型齿不一样的是,B型齿具有大的齿间距和排屑间隙,可以进行重切削和强力切削。标准规格的锯片铣刀一般做成双刃和并带有凸台。可以在B型齿的基础上订购BW型齿(BW齿型是在B型齿的基础上加倒角)。

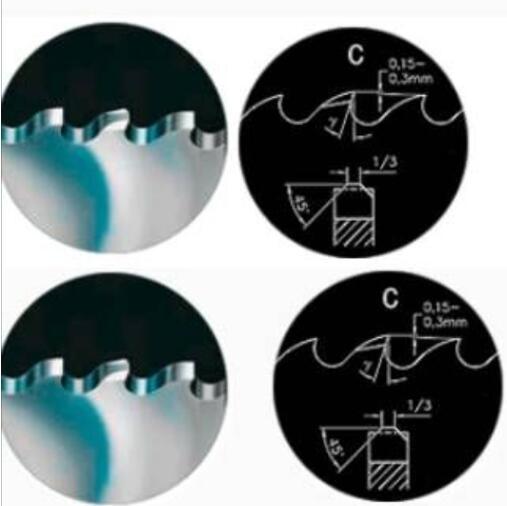

The teeth consist of roughing teeth and finishing teeth. The roughing tooth is chamfered from both sides and in its cutting part is 0,15-0,30mm bigger than the finishing one. Chips are cut into three parts and that’s why their removing is much more efficient. Perfect breaking prevents from blocking the cutting area and avoids poor tool life or even tool breakage due to the tooth clogging. It is recommended to cut solid materials.

德标DIN 1838 C 的锯片铣刀刀齿由粗切齿和精切齿组成,粗切齿两侧倒角,而且粗切齿比精切齿高0,15-0,30mm。 碎屑会被切成3片,所以排屑效果会非常好。这样的设计完美的解决了切割区域的刀尖易碎的问题,而且避免了阻塞碎屑导致的齿尖崩裂。可以用来加工各类固体金属材料。

如需了解德标1837A密齿型锯片铣刀可查看锐正动态,更多锯片铣刀产品信息可咨询锐正客服:15962364625或添加企业QQ:6037437207.